THE LEADING PROVIDER OF ENGINEERED PRODUCTS FOR THE CONCRETE CONSTRUCTION INDUSTRY

ITEMS AVAILABLE

PROJECTS WORLDWIDE

YEARS OF INDUSTRY LEADERSHIP

From our 17,000 hard-working products to our 1200+ dedicated people, Dayton Superior is all about building strength. As the leading single-source provider of concrete accessories, concrete chemicals, and concrete forming products for the non-residential construction industry, we deliver strong, proven products and build strong relationships built on integrity, responsiveness and unwavering support.

April's Superior Deal of The Month is Here!

A55 - Sure-Lock® Tie

Visit Product Page

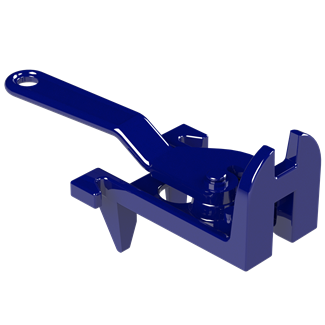

A56 Sure-Lock® Bracket

Visit Product Page

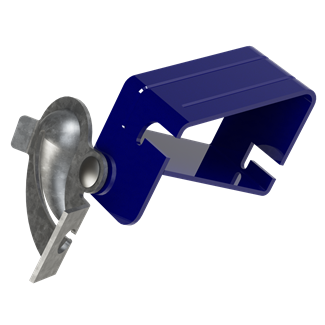

A57 Sure-Lock® Strongback Clamp

Visit Product Page

A81 Jahn® "A" Bracket

Visit Product Page

A82 Jahn® "C" Bracket

Visit Product Page

G27 Round Stakes

Visit Product Page

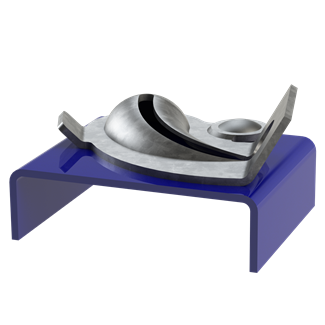

A16 Omni Wedge

Visit Product PageResources

ENGINEERING SERVICES

Engineered Precision When There's No Margin for Error

Dayton Superior engineers have the industry’s deepest expertise in every area of concrete construction, including all foundation types, commercial buildings, pre-cast and tilt-up, and highway projects.

Because you can’t afford even

one mistake, our team will perform with precision throughout the design, build and maintenance stages of your project.

TRAINING CLASSES & VIDEOS

Let Our Knowledge Build Yours

Dayton Superior training is a powerful, cost-effective way to stay current with products, technology, safety and trends.

Our industry pros share their expertise through engaging presentations, hands-on practice, classes, demonstrations and

AIA continuing education.

Dayton Superior Careers

Join An Amazing Team

We are committed to core values that influence every aspect of our business.

They are the principles that guide our decisions.

Who we are. What we do. How we do it.

-

1125 Byers Road Miamisburg, OH 45342

-

info@daytonsuperior.com

-

800-745-3700